Lessons from COVID-19: How Supply Chains Can Withstand the Next Trade Shock

This is an AArete Profitability Improvement solution

The word of the week: tariff. Throughout election season and into the new administration, tariffs have been a hot topic. Now that they are here, the big question is – how are companies responding?

The good news: this isn’t a surprise. Retailers, manufacturers, consumer product companies, and other businesses have been preparing for the impact ever since Trump announced his intent to run in the 2024 presidential election.

Just a few years ago, the COVID-19 pandemic upended global supply chains, triggering rapid and often reactionary responses. While tariffs represent the latest challenge in an ongoing strain on supply chains, they raise an important question: Will businesses manage these disruptions the same way they did during the pandemic or are there key differences?

Unlike Covid-19, which blindsided the world, tariffs are something businesses have had time to anticipate. Both events significantly impact the flow of goods and the broader economy, but the strategies for navigating them look very different. Let’s explore what businesses have learned and how they’re adapting this time around.

Global Supply Chain Stress Test, Part 2

The Covid-19 pandemic exposed vulnerabilities across global supply chains, with travel restrictions, factory shutdowns, and labor shortages causing widespread disruption. As economies rebounded, rising ocean freight and transportation costs compounded the challenges. Now, tariffs present a new – but anticipated – stress test. While different from a global health crisis, tariffs are once again putting pressure on supply chains. The good news? Businesses have had time to prepare, and recent disruptions have strengthened supply chain resilience.

How Tariffs are Stressing Supply Chains

Unlike pandemic-related disruptions, tariffs are policy-driven measures designed to protect domestic industries. However, they also disrupt global trade by increasing the cost of doing business – particularly with China, Canada, and Mexico. Affected products face price hikes and supply chain challenges, but many organizations have been proactive in mitigating these risks through strategic planning.

5 key strategies businesses are using to adapt:

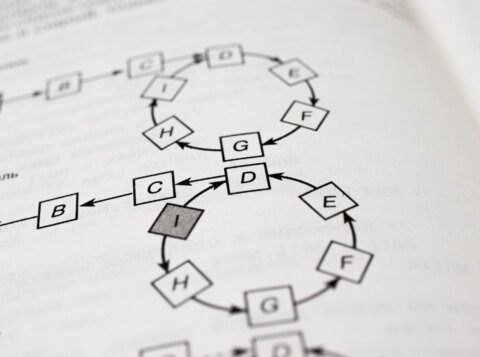

1. Alternative Sourcing

The simple solution continues to be diversifying your supply chain through alternative sourcing strategies. Organizations are constantly reviewing this due to changing costs in labor and the maturity of considerable alternative countries to support manufacturing needs and product development. A shift away from China to Vietnam or Cambodia has already begun and is expected to accelerate as trade costs with China rise.

2. Strengthening Supply Chain Resilience

The pandemic taught us how to quickly pivot, evaluate alternative suppliers, and adjust to economic fluctuations. These lessons in agility and resilience are now being applied to navigate tariffs to sustain stable supply chains despite policy changes.

3. Smart Inventory Management

Unlike during the pandemic – when companies resorted to stockpiling – many businesses have found that forward-buying inventory hasn’t been a necessary response to tariffs. Instead, organizations with strong inventory management strategies are optimizing their stock levels and balancing inventory costs without over-committing working capital.

4. Sharing the Costs

Global manufacturers are equally affected by tariffs. The most common response is to go elsewhere but collaboration is key. To avoid friction and the need to onset new relationships, many companies are negotiating shared cost structures with their existing suppliers, ensuring no single party bears the full financial burden while maintaining strong supplier relations.

5. Cutting Costs Elsewhere

When cost increases are unavoidable, businesses are looking inward to identify other areas for savings. By reassessing margins, optimizing third-party vendor contracts, and streamlining operations, companies are offsetting tariff-related expenses while maintaining profitability.

The Market Outlook

While businesses are better equipped to handle the operational impact of tariffs, economic uncertainty presents a new challenge. Retaliatory tariffs from Mexico and Canada on U.S. goods have already begun, and experts anticipate further escalation. The unpredictability now lies not in the supply chain, but rather in the broader global economy.

Prepared for Today – But What About Tomorrow?

Supply chains are facing disruption once again, but this time, businesses are prepared. Past experiences have provided valuable lessons in resilience and adaptability. However, true preparedness goes beyond responding to the current challenge – it requires anticipating and planning for whatever comes next.

Learn more about AArete’s Strategy & Change solutions