Tackling Tariffs in 2025 and Beyond

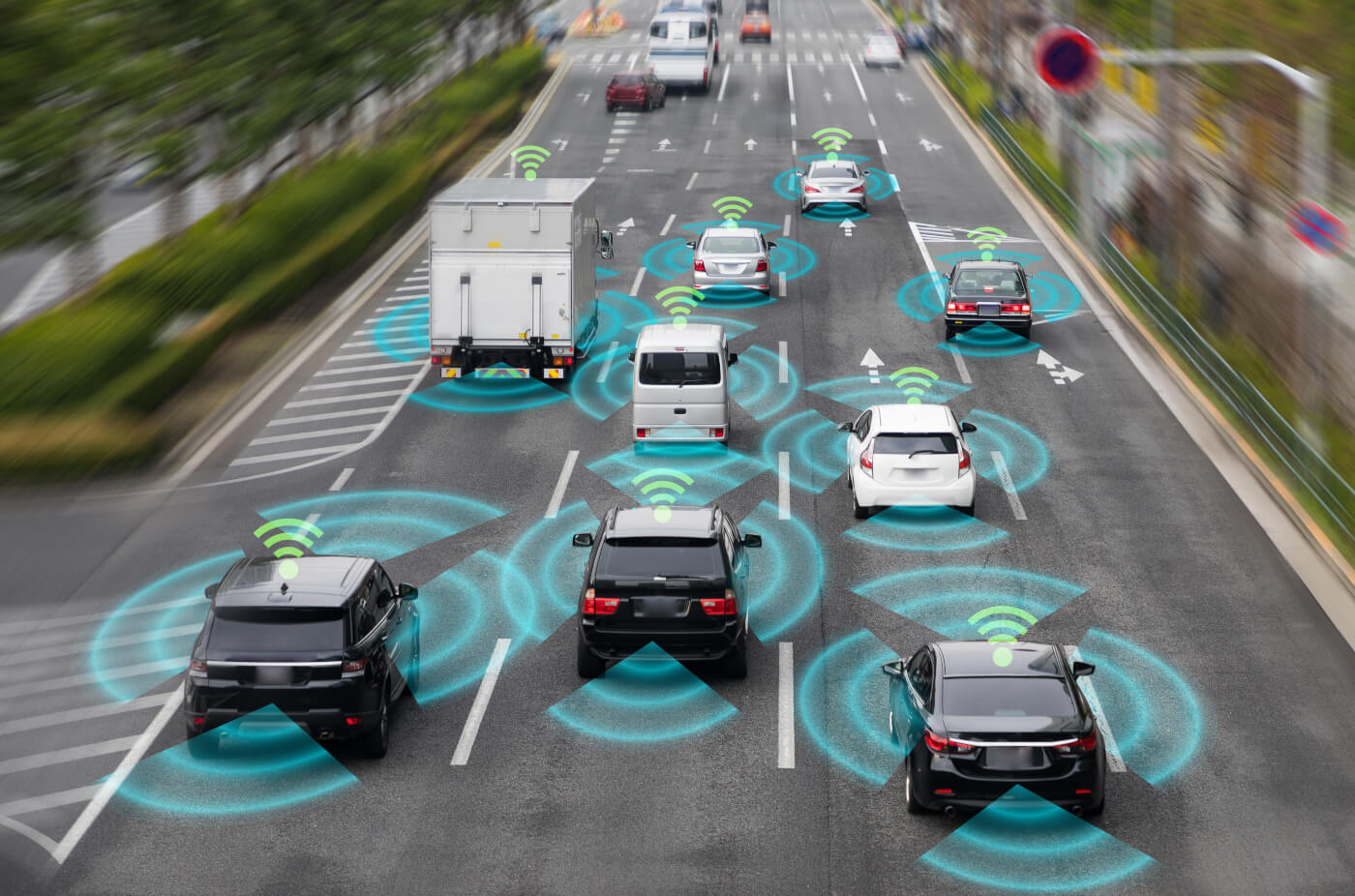

Imagine waking up to find that life just became 25% more expensive overnight. That time has come. Now what? Are your suppliers scrambling or your margins shrinking, leaving you with challenging decisions; or were you prepared? Regardless, it’s not business as usual and change is imminent. Do you plan on passing the cost onto customers, absorbing the hit, or finding a more strategic way to pivot? Tariffs did not come unexpected and have parallels to disruptions of the past. Organizations that are proactive in strategic planning, supplier negotiations, and creative cost management will come out ahead.

Tariffs may be unavoidable, but they don’t have to be devastating. Here are the top strategies companies can implement to offset these costs and stay competitive:

1. Alternative Sourcing: Diversify Your Supply Chain

A single-source supply chain is a liability in today’s volatile trade environment. Businesses are taking proactive steps to shift production to lower cost of trade countries such as Vietnam, Thailand, or Cambodia. All cost-effective alternatives to China. Organizations should have already engaged multiple suppliers across different countries to avoid over-reliance on one market. Companies that prepared for trade instability years ago are already reaping the benefits of diversified supply chains, reducing both costs and geopolitical risk.

2. Balance Costs: Share the Tariff Costs with Manufacturers

Many businesses assume that when tariffs hit, they must absorb the full impact—but negotiating with suppliers can be a game-changer. Three different ways to approach this include:

- Renegotiating contracts to share the burden of tariff increases between buyers and manufacturers.

- Exploring joint investments in production shifts, where suppliers and buyers work together to move manufacturing to lower-cost locations.

- Leveraging long-term partnerships for better pricing and supplier concessions in exchange for contract stability.

Companies that treat suppliers as strategic partners rather than just vendors are finding ways to distribute costs more equitably.

Organizations that are proactive in strategic planning, supplier negotiations, and creative cost management will come out ahead.

3. Go Beyond Tariffs: Take a Holistic Vendor Cost Reduction Approach

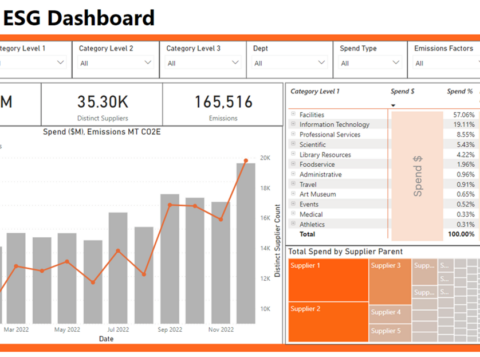

Instead of focusing solely on tariff-affected goods, there is an opportunity to assess company-wide cost reductions offsetting the impact. Considerable strategies include:

- Consolidating purchases to gain volume discounts across a broader range of products.

- Reevaluating total supplier spend to improve your contract structures.

- Investing in automation and technology to drive efficiency and reduce operational costs.

By taking a holistic view of cost reduction, companies can maintain profitability without simply passing tariff costs to customers, aiding customer retention.

4. Tariff Engineering: Optimize Product Classification

A lesser known, analysis intensive but powerful strategy, tariff engineering involves legally adapting a product’s design, materials, or assembly process to reduce tariff exposure. This can be done by:

- Modifying components and altering product classifications to qualify for lower tariff brackets

- Changing packaging and labeling to meet the criteria of a lower-duty product category.

- Splitting shipments or modifying assembly locations to take advantage of more favorable trade regulations.

It’s important for supply chain teams to work closely with customs experts to effectively meet regulatory compliance while minimizing tariff costs. This is one that may change daily as tariffs expand or shrink to more targeted product lines.

5. Meet Market Needs: Adjust Pricing Models or Explore New Markets

For some businesses, adjusting pricing models can help absorb tariff costs without shocking customers. Minimize customer pushback through slow or gradual price increases. Evaluate bundling products together or explore new markets. There is an uncertainty on the global economy and organizations need to develop different scenarios to understand the price sensitivity of their customer and the potential impact to their business.

Navigate Tariffs with Targeted Scenario Planning; Do Not Panic The latest round of tariffs are a new, but not an unexpected challenge. Companies that plan strategically can outmaneuver rising costs while maintaining competitiveness. Disruption creates another level to create a competitive advantage from your competitors. By leveraging alternative sourcing, supplier negotiations, holistic cost reductions, tariff engineering, and pricing strategies, businesses can minimize financial strain and strengthen their supply chains for the future. In times of uncertainty, those who adapt quickly and think creatively will emerge stronger than before.

Meet the Author

Tyler Higgins

Managing Director